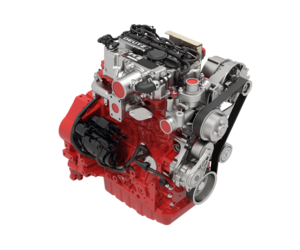

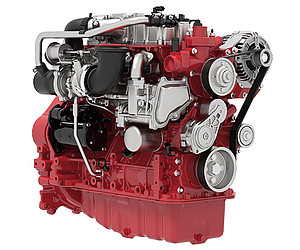

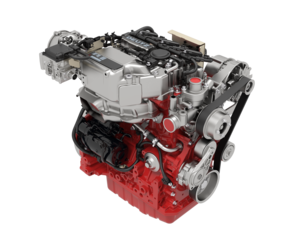

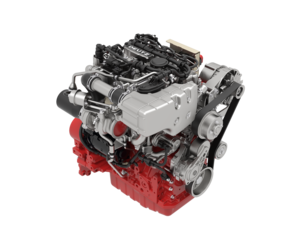

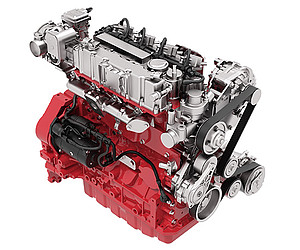

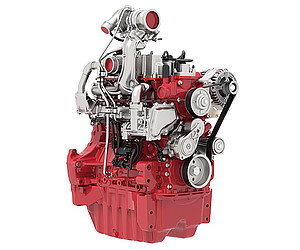

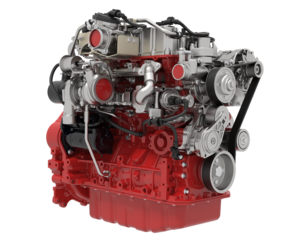

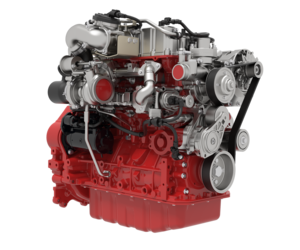

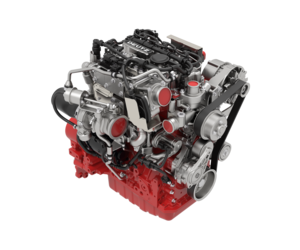

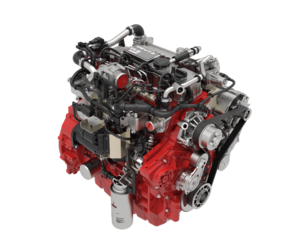

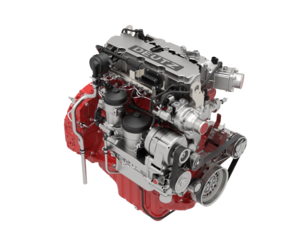

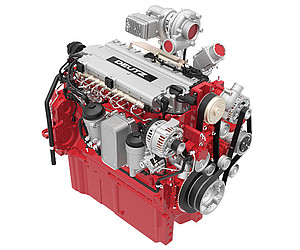

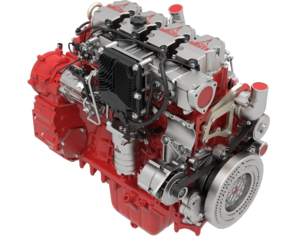

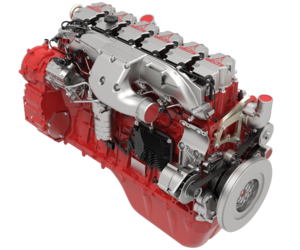

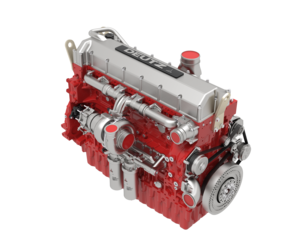

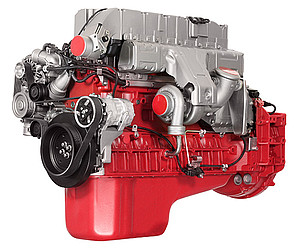

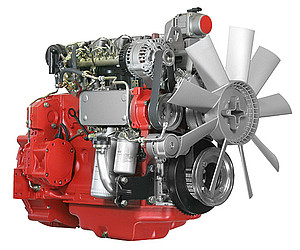

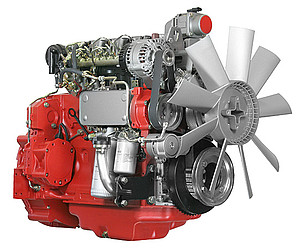

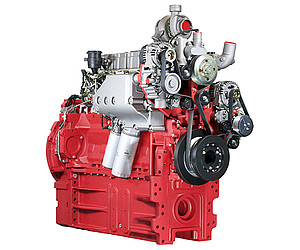

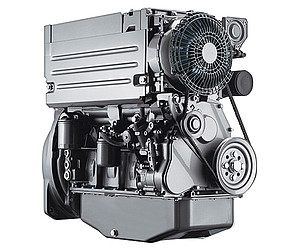

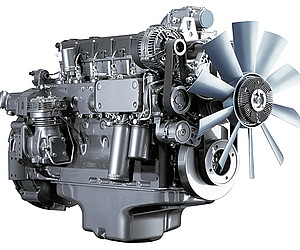

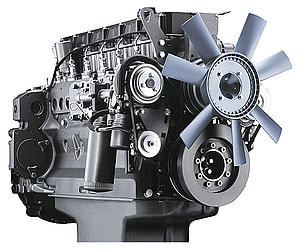

TCD 12.0 V6

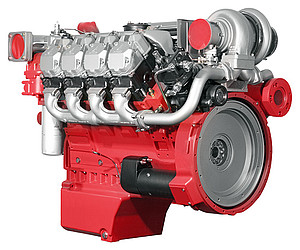

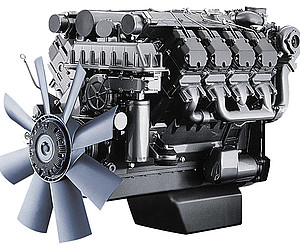

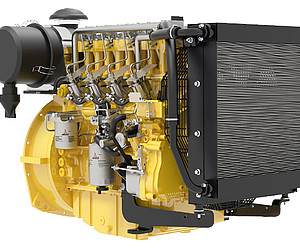

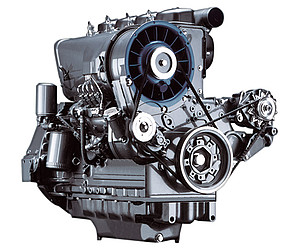

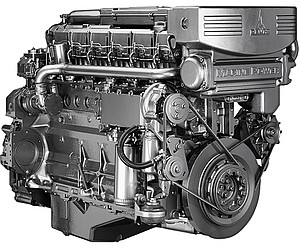

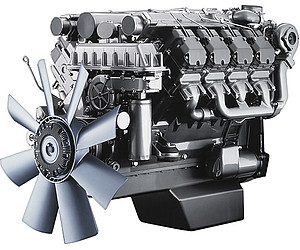

Water-cooled, V version (90°) 6- cylinder engine with turbocharging and charge air cooling.

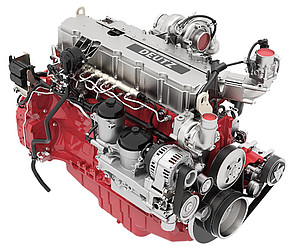

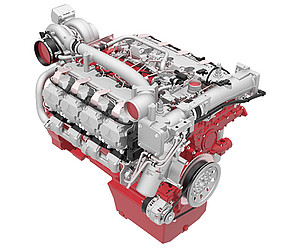

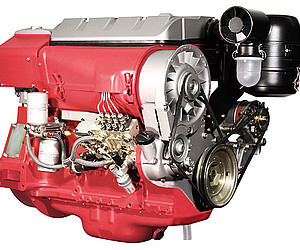

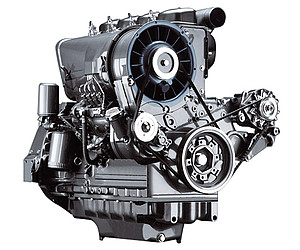

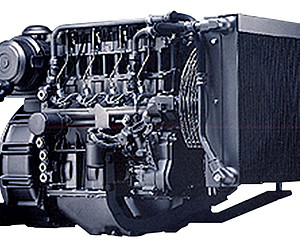

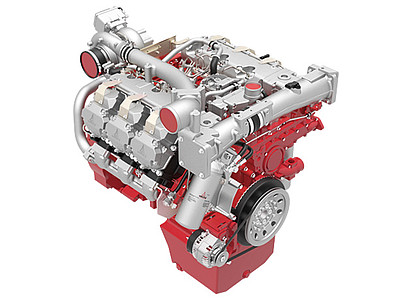

Engine and exhaust aftertreatment (EAT) are optimised for highest total system efficiency and thus ensure lowest consumption and total operating cost.

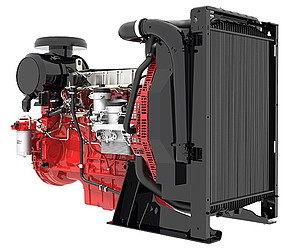

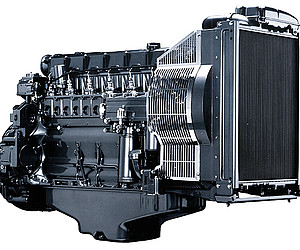

Thanks to SCR technology, the cooler sizes do not need to be enlarged in comparison with Tier 3 engines. Fuel consumption is reduced. (applicable for Stage IIIB and IV)

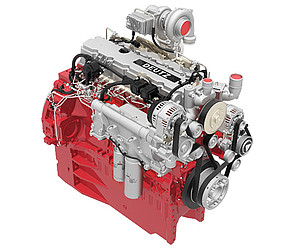

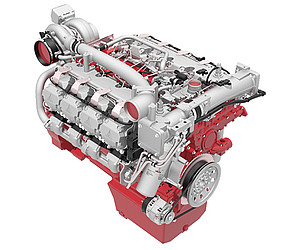

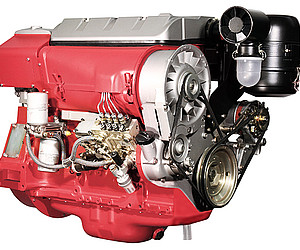

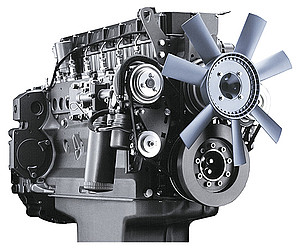

Consistent installation and connection dimensions of the engine facilitate the changeover of existing installations to the next stage of the emission laws.

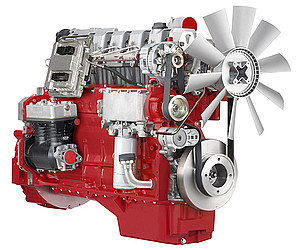

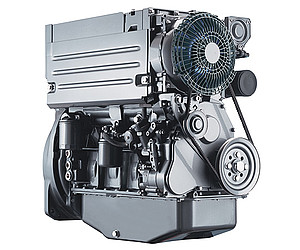

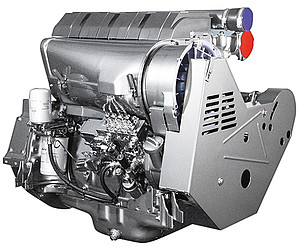

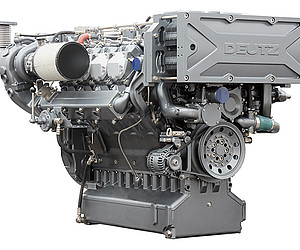

The engines have a modular exhaust aftertreatment system (EAT) with components from the DVERT® kit and optional configuration variants. This means a high flexibility in machine integration for the OEM.

Best cold starting performance even under extreme conditions.

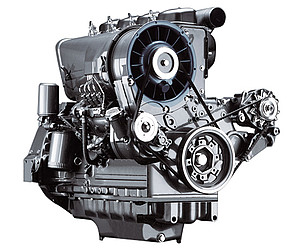

The extremely compact engine design and customer friendly accessories reduce the installation cost and increase the number of applications.

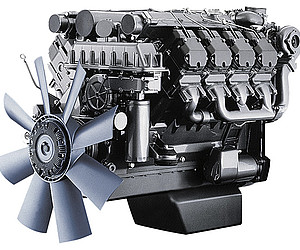

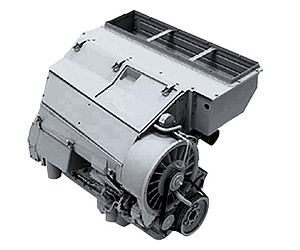

Both engines are also available as a flat version for extremely compact installations.

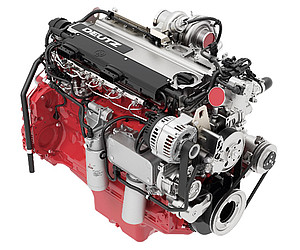

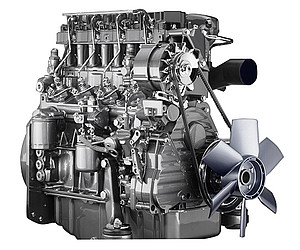

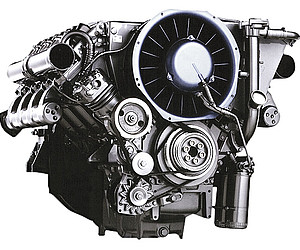

The powerful Common Rail injection system and the electronic engine control (EMR) with intelligent link to the drive management ensure optimum engine performance at low fuel consumption.

100% power take-off at flywheel and front end and additionally up to three PTO drives with a total torque of up to 520 Nm.

The engines meet the requirements of the EU Stage IIIB & IV and US EPA Tier 4 interim & Tier 4 with SCR. For EU Stage V a DPF is integrated into the EAT system. A variant with-out EAT is available as an option for less regulated markets.